One of Hottest for Rubber Sheet Epdm - Single-component waterproofing coating – Hongyuan Detail:

Single-component waterproofing coating

Single-component waterproofing coating is a polymer waterproof coating of reactive type of moisture-curable film. It is made of isocyanate and polyether as main material, mixing with solid agents, plasticizers and other additives and other additives using special technology by high temperatures dehydration polyurethane prepolymer and moisture in air, which forms tough, soft and jointless rubber waterproofing film on the substrate.

Product characteristics:

Single-component waterproofing coating, easy to apply, the requirement to moisture content of the base is not high, it can be applied on the more moist surface, also available on the surface it’s relative humidity is more big.

Polyurethane coating film has high strength and elongation, good elasticity, good high temperature and low temperature resistance, and high adaptability to substrate shrinkage and cracks.

Can coat 1mm to 3mm thick one time, coated film is dense, no bubbles, and high bonding power.

Not necessary to brush the substrate treatment agent on the various substrate which is up to the standard

Applicable scope:

Widely used in roofs, basement, toilet, swimming pool, and all kinds of industry and civil building waterproofing

Application technology:

Substrate need be firm, smooth, no sundries, inside corner and outside corner should be made into circular arc, the diameter of insider corner should be more than 50mm, and the outside corder should be more than 10mm.

Ingredient and dosage: according to application dosage, evenly mixing round o use.

Reference dosage: coating film dosage is about 1.3-1.5kg/sqm when the thickness is 1mm.

Large waterproof application, coating uniformity mixed coating with a rubber or plastic scraper, the thickness is onsistent, generally it is 1.5mm to 2.0mm, should be brushed in 3 to 4 times, the last time brushing should be done after the previous brushing cures and becomes film, and brushing at a ertical direction. Generally as a separate film-forming, for underground project board, should pave a layer of felt reinforced material in addition

Coating thickness: to underground project thickness is 1.2 to 2.0mm, generally 1.5mm; to toilet thickness is not less than 1.5mm; to multilayer waterproof of exposured roof construction thickness is not less than 1.2mm ; to one layer waterproof of grade Ⅲ waterproof, thickness is not less than 2mm;

Fishing layer application: scatter the cleaned sand before the last time brushing is not solidified.

Protection layer: on the coating film surface should do insulation protection as the design.

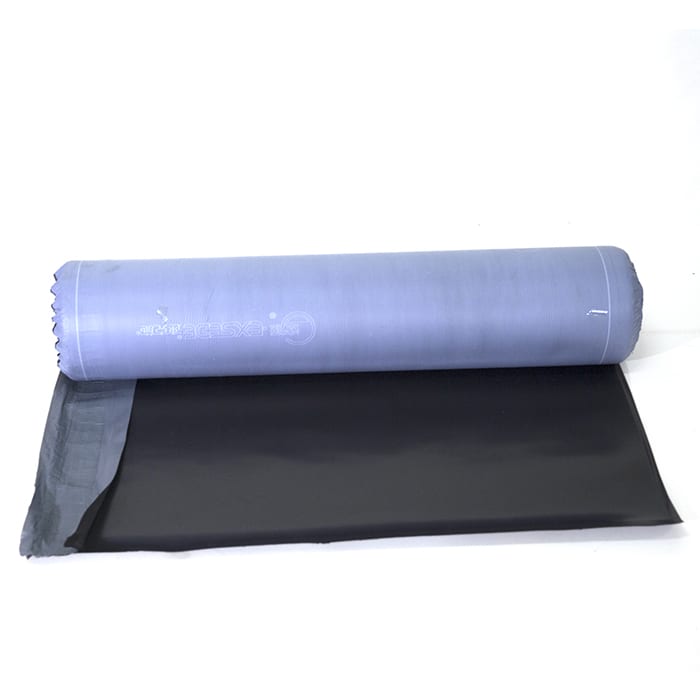

Product detail pictures:

Related Product Guide:

Birla Public School dedicates ‘chic sports and games’ to students | Polyurethane Waterproofing Membrane

MVRDV completes the couch for amsterdam tennis club | Asphalt Shingle

We emphasize advancement and introduce new products into the market each year for One of Hottest for Rubber Sheet Epdm - Single-component waterproofing coating – Hongyuan, The product will supply to all over the world, such as: Czech republic, Mauritania, Georgia, We have established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we are looking forward to even greater cooperation with overseas customers based on mutual benefits. Please feel free to contact us for more details.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.